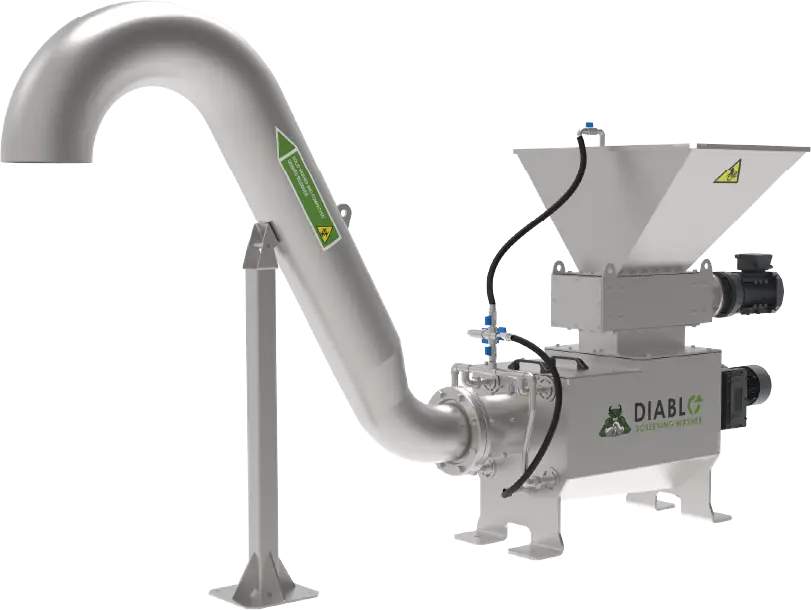

Diablo Screening Washer

Screw compactors consist of a screw compactor for washing, compacting, and conveying screened material and wet waste. The machine pushes the material through a pipeline or against a counter-pressure device, thus generating high forces capable of compacting and dewatering the material.

It dewaters up to a 40% of dry matter with a 90% volume reduction. Prior to separation, solids are grinded, thus reducing their size while increasing their surface. Consequently, the cleaning system may eliminate organic wastes more easily.

Therefore, we achieve a drier compact solid drastically reducing odours and getting the product ready to be taken to the landfill.

In short, the system implements 6 stages into a compact unit prepared for:

The double washing system allows a better release of organic matter, returning it to the purification process and not being sent to the landfill. The supervision and protection of the system is carried out through a PLC that captures the signals from the solid separation.